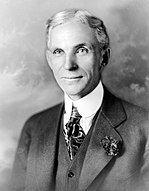

Henry Ford

Henry Ford was born in Dearborn, Michigan, United States on July 30th, 1863 and is the Entrepreneur. At the age of 83, Henry Ford biography, profession, age, height, weight, eye color, hair color, build, measurements, education, career, dating/affair, family, news updates, and networth are available.

At 83 years old, Henry Ford has this physical status:

Henry Ford (July 30, 1863-April 7, 1947) was an American industrialist and a business magnate who was responsible for the introduction of the assembly line technique in mass production. Although Ford did not invent the car or assembly line, he did design and produce the first automobile that many middle-class Americans could afford.

Ford converted the car from an expensive curiosity to a practical conveyance that would have a major influence on the 20th century's landscape.

The Model T automobile's introduction revolutionized transportation and American industry.

He was one of the world's richest and most well-known individuals.

He is credited with "Fordism": mass manufacturing of inexpensive products while also paying employees at high wages.

Ford had a global vision, with consumerism as the key to stability.

His continued commitment to lowering costs resulted in a number of technological and business advancements, including a franchise system that put dealerships throughout North America and in major cities on six continents.

Ford donated the bulk of his company to the Ford Foundation and arranged for his family to keep it running permanently. Ford was also known for his pacifism in the first years of World War I and for promoting antisemitic literature, including The Protocols of Zion, which had an alleged influence on Nazism and Adolf Hitler's development.

Early life

Henry Ford was born in Springwell Township, Michigan, on July 30, 1863. William Ford (1826–1905), his father, was born in County Cork, Ireland, to a family that had immigrated from Somerset, England in the 16th century. Mary Ford (née Litogot) was born in Michigan as the youngest child of Belgian immigrants; her parents died as a child; she was adopted by neighbors, the O'Herns. Margaret Ford (1867-1938), Jane Ford (c. 1868-1945), and Robert Ford (1873-1934) were among Henry Ford's siblings. Ford completed eighth grade at Springwell Middle School, a one-room school. He never went to high school; later, he took a bookkeeping course at a commercial college.

When he was 12, his father gave him a pocket watch. Hundreds of times, Ford dismantled and reassembled the timepieces of friends and acquaintances, earning the reputation of a watch repair man. Every Sunday, Ford walked four miles to their Episcopal church at twenty.

When his mother died in 1876, Ford was devastated. His father aspired to take over the family farm someday, but he resent farm work. "I never had a particular passion for the farm; it was the mother on the farm I loved," he later wrote.

Ford left home in 1879 to work as an apprentice in Detroit, first with James F. Flower & Bros. and later with the Detroit Dry Dock Co. He returned to Dearborn in 1882 to work on the family farm, where he became an expert at operating the Westinghouse portable steam engine. He was later hired by Westinghouse to maintain their steam engines.

When Ford was 12 years old in 1875, he recalled two major events. "The first automobile other than horse-drawn that I had ever seen" on the television, as he watched the Nichols and Shepard road engine operate. Ford built a "steam wagon or tractor" and a steam train, but "the boiler was not suitable for light vehicles," Ford said in his farm workshop, but "steam was not suitable for light vehicles." "I did not see the use of electricity because of the high cost of trolley wires," Ford continued, and "no storage battery was in sight of a weight that was practical." Ford built an Otto engine in 1885, and in 1887 he built a four-cycle version with a one-inch bore and a three-inch stroke. Ford started using a two-cylinder engine in 1890.

"I completed my first motor car, powered by a two-inch bore and a six-inch stroke in 1892, and then fastened to a belt and then to the rear wheel by a chain," Ford said. The belt was shifted by a clutch lever to control speeds of ten or twenty miles per hour, which was increased by a throttle. Other notables included 28-inch wire bicycle wheels, a foot brake, a 3-gallon fuel tank, and, eventually, a water jacket around the cylinders for cooling. "The machine was running to my partial satisfaction in the spring of 1893, giving the opportunity to try out the configuration and material on the road." Ford drove the car about 1000 miles between 1895 and 1896. In 1896, he built three of them in his home workshop, eventually building three more.

Career

Ford was a pioneer with the Edison Illuminating Company of Detroit in 1891. He had enough time and resources to devote his attention to his gasoline engine experiments after his promotion to Chief Engineer in 1893. These experiments came to an end in 1896 with the introduction of a self-propelled car, which he described as the Ford Quadricycle. On June 4, he test-droved it. Ford considered enhancing the Quadricycle after several test drives.

Ford attended a meeting of Edison executives in 1896, where he was introduced to Thomas Edison. Ford's automobile experiments were encouraged by Edison. Ford invented and built a second vehicle, completing it in 1898, after Edison encouraged it. Ford resigned from the Edison Company and founded the Detroit Automobile Company in 1899, owing to the success of Detroit lumber baron William H. Murphy. However, Ford's cars were of lower quality and higher price than Ford's. In the end, the firm was not profitable, and it was dissolved in January 1901.

In October 1901, Ford introduced, built, and raced a 26-horsepower vehicle with the support of C. Harold Wills. Murphy and other Detroit automakers formed the Henry Ford Company on November 30, 1901, with Ford as the chief engineer. Murphy brought in Henry M. Leland as a consultant in 1902, but Ford left the company with his name. Leland renamed the business the Cadillac Automobile Company after Ford was defunct, and the Cadillac Automobile Company was renamed Leland.

Ford also produced the 80+ horsepower racer "999," which Barney Oldfield was to win in a race in October 1902. Alexander Y. Malcomson, a Detroit-area coal dealer, gave Ford the support of an old acquaintance. To produce automobiles, they formed "Ford & Malcomson, Ltd." Ford went to work building a cheap car, and the pair leased a factory and contracted with a machine shop owned by John and Horace E. Dodge to make over $160,000 worth of parts. Sales were modest, and a crisis arose when the Dodge brothers requested payment for their first shipment.

Malcomson brought together another group of investors and persuaded the Dodge Brothers to fund a portion of the new firm. On June 16, 1903, Ford & Malcomson was reincorporated as the Ford Motor Company, raising $28,000 capital. Ford and Malcomson, Malcolm Couzens, Malcolm Couzens, and two of Malcomson's attorneys, John W. Anderson and Horace Rackham, were among the original investors. Gray was elected president of the company by a turbulent market. Ford then demonstrated a newly built car on Lake St. Clair's ice, going 1 mile (1.6 km) in 39.4 seconds and setting a new land speed record of 91.3 kilometres per hour (146.9 kilometres per hour). Barney Oldfield, the British racer who named this new Ford model "999" in honor of the day's fastest locomotive, was energized by its success, and the Ford brand was everywhere in the United States, making the Ford brand known throughout the country. Ford was also one of the Indianapolis 500's early backers.

On October 1, 1908, the Model T made its debut. The steering wheel was on the left, which every other company soon copied. The complete engine and transmission were enclosed; the four cylinders were cast in a solid block; the suspension used two semi-elliptic springs; The vehicle was very easy to handle and inexpensive to repair. It was so cheap in 1908 ($24,880 today) that by the 1920s, a majority of American drivers knew how to drive on the Model T, despite the fact that drivers were only familiar with the Model T's unique foot-operated planetary transmission and steering-column-operated throttle-cumulation system required a completely different set of skills to drive every other gasoline-powered vehicle of the time.

Ford built a massive publicity machine in Detroit to make sure every newspaper carried news and ads about the new product. The car was available in virtually every city in North America thanks to Ford's nationwide dealer network. As independent dealers grew wealthy and famous, not only were the Ford but also the concept of automobility; local motor clubs stepped up to assist new drivers and encourage them to explore the countryside. Farmers were always eager to sell, and Ford continued to market the car as a commercial device to support their company. Sales soared in the first year, with several years seeing 100 percent increases over the previous year. Ford introduced moving assembly belts to his plants in 1913, resulting in a dramatic rise in production. Although Ford is often credited with the theory, recent reports show that the idea and growth came from employees Clarence Avery, Peter E. Martin, Charles E. Sorensen, and C. Harold Wills.(See Ford Piquette Avenue Plant)

In 1914, sales hit 250,000 people. By 1916, when the price dropped to $360 for the basic touring vehicle, sales reached 472,000.

Model Ts made up half of all automobiles in the United States by 1918. All new cars were black; Ford wrote in his autobiography, "Any customer can have a car painted in the shade he wants so long as it is black." Model Ts were available in other colors, including red, before the production of the assembly line, which required black due to its quicker drying time. Ford fervently promoted and defended the model, and manufacturing continued as late as 1927; the final total production was 15,007,034. This record stood for more than 45 years, and was set in 19 years, and it was achieved in 19 years from the introduction of the first Model T (1908).

Henry Ford turned the presidency of Ford Motor Company over to his son Edsel Ford in December 1918. Henry retained final decision authority and occasionally reversed his son's's's decisions. Henry Ford and Sons founded a show of luring the remaining holdout stockholders of the Ford Motor Company to sell their shares to him before losing the majority of their value. (He was determined to have full authority over strategic decisions.) The ruse worked, and Ford and Edsel purchased all remaining stock from the other investors, giving the family sole ownership of the company.

During World War I, Ford founder Henry Leland and his son Wilfred purchased Lincoln Motor Co. The Lelands briefly remained to lead the company but were promptly banned from it. Despite this merger, Henry demonstrated virtually no enthusiasm for luxury automobiles in comparison to Edsel, who was determined to extend Ford into the luxury market. The original Lincoln Model L, which the Lelands had introduced in 1920, was still in production, but it wasn't until it became too old that it was no longer available. In 1931, the modernized Model K was introduced.

GM was quickly rising as the country's top automobile manufacturer by the mid-1920s. In contrast to Ford's inability in anything outside of the low-end market, GM president Alfred Sloan developed the company's "price ladder," whereby GM will sell an automobile for "every purse and purpose." Although Henry Ford, who was against replacing the Model T, now 16 years old, was mounting a bold new challenge as GM's entry-level division in the company's price ladder was uncovered. Ford has also resisted the increasingly popular notion of vehicle payment plans. Ford was required to relent and accept work on a new model after Model T sales dropped, with the company stopping production for 18 months. During this period, Ford built a massive new assembly plant in River Rouge for the new Model A, which was introduced in 1927.

GM also grew to the forefront of automotive styling under Harley Earl's Arts & Color Department, another segment of automobile design that Henry Ford did not fully comprehend or fully comprehend. Ford will not have a true equivalent of the GM styling team for many years.

Ford was advised by 1926 to build a new model after experiencing poor sales of the Model T. He pursued the project with a great deal of concern in the engine's chassis, and other mechanical components, but decided against the body's design. Despite Ford's admiration of himself as an engineer, he had no formal education and was unable to even read a blueprint. The majority of the actual research involved in designing the Model A (and then the flathead V8) with Ford supervising them closely and giving them overall direction. Edsel was able to prevail over his father's initial reservations about the inclusion of a sliding-shift transmission.

The result, which was the production of more than four million, the Ford Model A, which was introduced in December 1927 and 1931. The Ford company followed a five-year model change process that was previously introduced by its competitor General Motors (and is still in use by automakers today). Ford didn't have to finance companies until the 1930s, and Ford-owned Universal Credit Corporation became a major auto-financing company. Henry Ford has resisted many technological advancements, including hydraulic brakes and all-metal roofs, which Ford cars did not have until 1935–36. Ford dropped a bombshell with the flathead Ford V8, the first low-price eight-cylinder engine built in 1932. The flathead V8, which were used in Ford vehicles for 20 years, was the result of a classified project launched in 1930, and Henry considered a radical X-8 engine before committing to a conventional configuration. Ford was known as a hot rodding machine that was made in a fashion that was appropriate for hot rodding.

Ford didn't believe in accountants; he amassed one of the world's largest fortunes without ever having his company audited under his control. Ford had no way of knowing exactly how much money was collected and spent each month without an accounting department, and the company's bills and invoices were apparently estimated on a scale. Ford will not be a publicly traded company until 1956.

In addition, Ford launched Mercury in 1939 as a mid-range make to contend Dodge and Buick, but Henry Henry showed little enthusiasm for it during Edsel's insistence.

Ford pioneered "welfare capitalism" that was meant to improve the lot of his employees and, in particular, reduce the heavy turnover that caused many departments to fill 100 positions. Hiring and keeping the best employees was crucial to success.

Ford stunned the world in 1914 by giving a $5 per day wage ($140 today), which more than doubled the unemployment rate of the majority of his workers. The news "shot like a blinding rocket through the thick clouds of current industrial depression," a Cleveland, Ohio newspaper editorial said. The change was extremely profitable; rather than constant employee turnover, the best mechanics in Detroit flocked to Ford, increasing efficiency, raising productivity, and lowering training costs. On January 5, 1914, Ford introduced his $5-per-day service, boosting the minimum daily wage from $2.34 to $5 for eligible male employees.

Detroit was already a high-wage city, but opponents were expected to raise wages or lose their best employees. Ford's policy found that paying employees more would enable them to buy the cars they were manufacturing and therefore improve the local economy. He viewed the increase in wages as profit-sharing tied to rewarding those who were most efficient and of good character. It may have been Couzens who convinced Ford to offer the $5-day salary.

Real profit-sharing was provided to employees who had worked with the company for six months or more, and, more importantly, lived in a manner that Ford's "Social Department" approved. Heavy drinking, gambling, and even deadbeat dads were banned from attending a festival. To maintain employee standards, the Social Department employed 50 investigators and support workers; a substantial number of employees were able to qualify for this "profit-sharing."

Ford's entry into his employees' personal lives was deeply revealing, and he backed away from the most difficult aspects of the process. By the time he wrote his 1922 memoir, he had written of the Social Department and the private conditions for profit-sharing in the past. "Paternalism has no place in the industry," he said. Welfare work that involves probing into employees' personal issues is out of date. Both men and women need advice and some men need assistance, and all this should be done for decency's sake. However, the more effective investment and involvement scheme would help the company to solidify the market and improve the company's reputation, as well as any social work carried out. We have changed the method of payment without changing the principle."

Ford introduced a new, reduced workweek in 1926, in addition to raising his employees' salaries. In 1922, Ford and Crowther referred to it as six 8-hour days, a 48-hour week, but in 1926, it was announced as five eight-hour days, giving a 40-hour week. The service seems to have began on Saturday as a workday before being postponed until a few days later. The Ford Motor Company's factory workers in May 1, 1926, converted to a five-day, 40-hour workweek, with the company's administrative staff assisting the change in August.

Ford wanted to raise productivity, as employees were likely to put more effort into their jobs in exchange for more leisure time. Good leisure time, according to Ford, gives employees additional time to buy and consume more products. However, charitable causes also played a role. "It's time to get rid of the belief that workingmen's leisure is either 'lost time' or a class privilege," Ford said.

Ford was adamantly against labor unions. In Chapter 18 of My Life and Work, he shared his thoughts on unions. Despite their apparent noble intentions, they felt they were being more influenced by executives who would end up doing more harm than good for employees. Most wanted to restrict productivity as a way to raise jobs, but Ford dismissed this as self-defeating because, in his view, work was absolutely essential for economic growth.

He said that productivity gains that had discouraged certain occupations would also help the economy and create new jobs elsewhere, whether within the same company or elsewhere. Ford also believed that union representatives had a perverse motivation to perpetuate socioeconomic crises in order to hold their positions. In addition, he believed that smart managers should do right by their employees because doing so would maximize their profits. However, Ford did acknowledge that some bosses were actually too bad at managing to understand this information. However, Ford believed that if good managers such as himself could defend the misguided people from both left and right (i.e., both socialists and poor-manager reactionaries), they would eventually develop a socio-economic framework in which neither bad management nor poor unions would have enough funding to continue operating.

Ford promoted Harry Bennett, a former Navy boxer, to head the Service Department in an attempt to prevent union activity. Bennett used a variety of coercion techniques to discourage union union membership from occurring. During the Great Depression, unemployed Detroit autoworkers staged the Ford Hunger March to Henry Ford's Ford River Rouge Complex on March 7, 1932. Over sixty workers were wounded and five people were killed in the Dearborn police department and Ford security guards opened fire on civilians, resulting in over sixty injuries and five deaths. Bennett's security men defeated United Automobile Workers (UAW), including Walter Reuther with clubs, on May 26, 1937. As Bennett's guys were beating the UAW representatives, the supervising police chief on the scene was Carl Brooks, an alumnus of Bennett's Service Department, and [Brooks] "did not have orders to intervene." Photographs of the wounded UAW workers appeared in newspapers the following day, and The Battle of the Overpass was later identified as The Battle of the Overpass.

Edsel, the company's president, in the late 1930s, was convinced that Ford would have to reach a collective bargaining deal with the unions because the brutality, work disruptions, and bitter stalemates could not go on for ever. Ford, who had the final veto in the company even though not an official one, refused to cooperate. Bennett stayed in charge of negotiating with the unions trying to organize the Ford Motor Company for many years. Bennett's memoir makes it clear that Ford's motive in sending Bennett in charge was to ensure no deals were ever reached.

Despite protests from the rest of the industry and even the US government, the Ford Motor Company was the last Detroit automaker to recognize the Union. The River Rouge Plant was closed in April 1941 after a union sit-down strike. Sorensen recalled that a troubled Henry Ford was so close to going broke with a threat to abandon the business rather than cooperate. Nonetheless, Clara's wife warned him that if he failed the family company, he would leave him. It would not be worth the chaos it would bring, in her view. In retrospect, Ford followed his wife's ultimatum and even agreed with her. The Ford Motor Company went from the most adamant holdout among automakers to the one with the most favorable UAW contract terms in less than a year. In June 1941, the deal was signed. "It was one of the most responsible things Harry Bennett ever did when he brought the Union to this plant," Ford told Walter Reuther about a year later.Reuther inquired, "What do you mean?"

"You've been fighting GM and the Wall Street crowd," Ford replied. Now you're in here, and we've got you a union store and more than you expected out of them.That puts you on our side, doesn't it?

We should all be battling GM and Wall Street together, eh?Ford introduced Liberty engines to the aviation market during World War I, as well as other automobile companies. After the war, it returned to auto manufacturing in 1925, when Ford acquired the Stout Metal Airplane Company.

The Ford 4AT Trimotor, often described as the "Tin Goose" due to its corrugated metal construction, was Ford's most successful plane. It used Alclad, a new alloy that combined aluminum corrosion resistance with the strength of duralumin. The plane was similar to Fokker's V.III-3 million, and some believe Ford's engineers shamstically measured the Fokker plane and then copied it. On June 11, 1926, the Trimotor was the first commercial airline in the United States, transporting around 12 passengers in a rather uncomfortable manner. Several variations of the U.S. Army's specialized weapons were also used by the US Army. Ford has been lauded by the Smithsonian Institute for its contributions to the aviation industry. 199 Trimotors were built before it was discontinued in 1933, when the Ford Airplane Division came to a halt due to poor sales during the Great Depression.

Ford opposed war, which he regarded as a tragic waste, and praised causes that opposed military involvement. Ford became highly critical of those who felt financed war, and he tried to prevent them from happening again. Rosika Schwimmer, a pacifist, gained traction with Ford, who agreed to fund a Peace Ship to Europe, where World War II was raging. He was one of 170 other peace campaigners. Reverend Samuel S. Marquis, Ford's Episcopalian pastor, accompanied him on the trip. From 1913 to 1921, Marquis was the head of Ford's Sociology Department. Ford spoke to President Woodrow Wilson about the mission, but there was no government help. His group travelled to neutral Sweden and the Netherlands to speak with peace campaigners. Ford's ship, which had been a point of much mockery, was abandoned as soon as it landed in Sweden. Ford criticized "German-Jewish bankers" for starting the conflict in 1915.

Ford's reputation as a leading industrialist gave him a world view that war was a wasteful waste that retarded long-term economic development, according to biographer Steven Watts. The losing team of the war suffered significant injuries. Small businesses were particularly affected by the fact that it takes years to recover. In several newspaper articles, he argued that a concentration on company growth would save warfare, because "any man who makes an article would make the very best he can in the most possible way at the very least possible cost, the world will not have to search for weapons, recruit employees, and achieve long-term profits." Ford admitted that munitions manufacturers enjoyed wars but that instead, manufacturers would instead focus on producing and selling useful products, recruiting employees, and generating steady long-term profits."

To raise the British food supply, Ford's British factories made Fordson tractors, as well as trucks and warplane engines. Ford went silent on foreign policy as the United States entered the war in 1917. His company has grown into a major weapons manufacturer, particularly the Liberty engine for warplanes and anti-submarine boats.: 95–100, 119

President Woodrow Wilson, a Democrat, encouraged Ford to run for a Michigan seat in the US Senate in 1918, with the war raging and the League of Nations becoming a growing problem in international politics. Wilson believed that Ford could tip the balances in congress in favour of Wilson's planned League. "You are the only man in Michigan who can be elected and help bring about the peace you so desire," Ford wrote. Ford wrote back: "If they want to elect me, let them do so, but I won't make a penny." Ford did run, however, and came within 7,000 votes of winning out of a total of more than 400,000 cast statewide. Truman Newberry, the Republican nominee, and a former United States Secretary of the Navy, were disqualified in a close election. Ford remained a stal Wilson and League supporter. Ford helped with the attendant expenses while Wilson was on a big speaking tour in 1919 to promote the League.

Ford had opposed the United States' entry into World War II and continued to believe that international industry would bring the peace that would bring about wars. "The war was a product of cynical financiers who needed to make money from human destruction," Ford said. He went so far as to say that the torpedoing of U.S. merchant ships by German submarines was the result of financier war-makers' conspiratorial activities. Ford's code for Jews, according to the financiers, who had also accused Jews of referring to the First World War. He did not want to deal with belligerents in the run-up to World War II and 1939. He never liked or entirely trusted the Franklin Roosevelt Administration, and believed Roosevelt was pulling the United States closer to war. Ford continued to do business with Nazi Germany, including the production of war equipment. Nonetheless, he has promised to develop warplane engines for the British government. Even though Ford Motor Company did not have an aircraft manufacturing plant at the time, he predicted that one day, it would be able to produce 1,000 U.S. warplanes a day. 430 Ford was a pioneer on the America First Committee against World War II involvement, but he was forced to resign from the executive board when his membership became too controversial.

Ford-Werke contravened Article 31 of the 1929 Geneva Convention, beginning in 1940, with the requisition of between 100 and 200 French POWs to serve as slave labourers.

When Rolls-Royce needed a U.S. manufacturer as an additional source for the Merlin engine (as fitted to Spitfire and Hurricane fighters), Ford first agreed to do so and then reneged. When the United States opened in December 1941, he "legged behind the war effort."

Ford ordered Ford Motor Company to build a massive new purpose-built aircraft factory in Willow Run, Michigan, before the United States entered the war, responding to President Roosevelt's call for the "Great Arsenal of Democracy" in December 1940. In 1941, Ford laid the first complete B-24 on Willow Run, and the first complete B-24 arrived off the line in October 1942. It was the world's biggest assembly line at 3,500,000 sq ft (330,000 m2). The Willow Run plant at its peak in 1944 produced 650 B-24s per month, and by 1945, Ford was completing each B-24 in eighteen hours, with one rolling off the assembly line every 58 minutes. At Willow Run, Ford produced 9,000 B-24s, half of the 18,000 total B-24s made during the war.: 430

Henry Ford fully recovered control of the company when Edsel Ford died of cancer in 1943, at the age of 49, but a string of strokes in the late 1930s left him increasingly incapacitated, and his mental capacity was fading. Ford was increasingly marginalized, and others made decisions in his name. Ford's Service Unit, Ford's top engineer and production executive, Charles Sorensen, a key engineer and production executive, and Harry Bennett, the head of Ford's Service Unit, Ford's secret service unit, who enforced discipline on Ford workers, were among the company's key executives ruled by a handful of senior executives led by Henry Bennett, a key engineer and production executive; and Ford's Service Unit chief, who spied on and enforced discipline against Ford's Sorensen was chastised of the fame he received and pushed Sorensen out in 1944, but Ford became jealous of the attention. Ford's incompetence sparked discussions in Washington about whether wartime government intervention or by starting a revolt among executives and directors.

Nothing happened before 1945, when bankruptcy was a serious threat to Ford's widow, Clara and Edsel's widow, Eleanor, confronted him and asked that the company be ceded power to his grandson Henry Ford II. If he declined, they threatened to sell off their shares, which amounted to three quarters of the company's total shares. Ford was reported enraged, but the company had no choice but to give in. The young man took over and fired Harry Bennett as his first act of business.

Later career and death

When Edsel Ford, the President of Ford Motor Company, died of cancer in May 1943, the elderly and ailing Henry Ford decided to assume the presidency. By this time, Ford, which was close to 80 years old, had suffered several cardiovascular events (variously characterized as heart attacks or strokes) and was physically inefficient, suspicious, and generally not prepared for such large responsibilities.

The majority of the directors did not want to see him as president. Despite being without a formal executive title for the previous 20 years, he had always had de facto influence over the company; the board and the leadership had never fully opposed him; this time was no different. He was hired by the producers, and he served until the end of the war. During this time, the company began to decline, losing more than $10 million a month ($156,600,000.000 today). President Franklin Roosevelt's administration had been considering a government takeover of the company in order to ensure continued war production, but the proposal never came true.

Despite his health, Ford ceded the company's presidency to his grandson Henry Ford II in September 1945 and retired. He died of a cerebral hemorrhage at Fair Lane, his family's estate in Dearborn, on April 7, 1947, at the age of 83. At Greenfield Village, where up to 5,000 people per hour streamed past the casket, there was a public viewing. In Detroit's Cathedral Church of St. Paul, funeral services were held, and he was buried in the Ford Cemetery in Detroit.